By Editors of Fine Woodworking

ISBN-10: 156158018X

ISBN-13: 9781561580187

ISBN-10: 163186131X

ISBN-13: 9781631861314

ISBN-10: 1631862170

ISBN-13: 9781631862175

ISBN-10: 1631862189

ISBN-13: 9781631862182

ISBN-10: 1631862197

ISBN-13: 9781631862199

ISBN-10: 1631862200

ISBN-13: 9781631862205

Nothing beats seeing your woodworking on reveal or the response you get should you provide your paintings as a present. the matter is discovering sufficient time to accomplish the entire initiatives you need to do. This publication can help. Small Woodworking Projects is a set of approachable tasks from high-quality Woodworking journal that might tempt and fulfill even the main discriminating of woodworkers.

You don't want an enormous store, formal education or lots of unfastened time to construct the worthwhile, beautiful items during this assortment. All you would like are uncomplicated woodworking instruments and abilities. initiatives diversity from containers excellent for reward giving, to instruments for the workshop, to goods excellent for the house and so they run the gamut from uncomplicated to complicated. With the exploded drawings, specified plans, and transparent step by step directions tremendous Woodworking is understand for, this can be a should have assortment for each woodworker.

Read Online or Download Small woodworking projects PDF

Similar woodworking books

Portable Power Tools (Art of Woodworking)

The artwork of Woodworking - moveable strength instruments

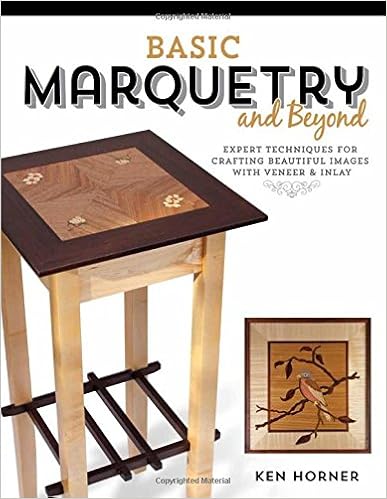

Книга Marquetry MarquetryКниги English литература Автор: Pierre Ramond Год издания: 2003 Формат: pdf Страниц: 218 Размер: fifty five. 7 MB ISBN: 0892366850 Язык: Русский0 (голосов: zero) Оценка:For centuries the artwork of marquetry has been situated in Paris, the place the culture has been transmitted in basic terms inside of workshops centred within the Faubourg Saint-Antoine.

Field making is ideal for starting woodworkers attracted to gaining talents, experimenting with layout, and feeling delight at a undertaking that may be accomplished with no the time and cost dedication of a larger venture. This e-book will provide simple designs, in addition to many adaptations to educate various woodworking ideas whereas the reader creates a pragmatic merchandise or a present that would turn into an heirloom.

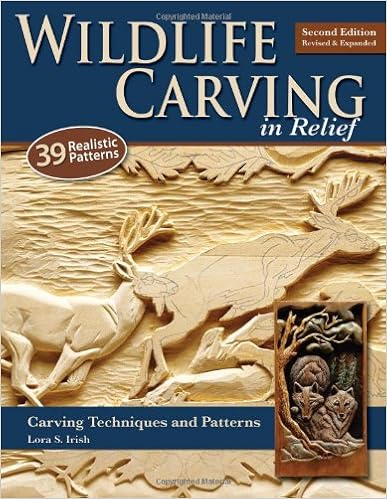

Think the wonderful thing about a deer working during the wooded area, a buffalo status on a prairie at sundown, or a mallard drake winging during the cattails-all stunningly carved in wooden lower than inches thick. this can be the artwork of flora and fauna reduction carving, the place dependent images of animals and birds are dropped at lifestyles with carving options which are effortless to grasp and acceptable to any kind of woodcarving you opt to do.

- Green Woodworking: Handcrafting Wood from Log to Finished Product

- Christmas Ornaments for Woodworking

- Cabinetmaking (The Art of Woodworking)

- Fantasy & Legend Scroll Saw Puzzles

- Wood shop plans

- Making Collectible Santas and Christmas Ornaments in Wood

Extra resources for Small woodworking projects

Sample text

Glue up the box (I use yellow glue), clamping evenly across the faces of the joint. Even pressure is important to avoid putting tension in the box. Later, when you saw apart an unevenly clamped box, the top and bottom could twist in different directions, making a bad fit. If the pins protrude from the tails, you’ll need to make clamping cauls with fingers that put pressure only on the tails. Let the glue cure thoroughly, then sand the exterior of the box to about 320 grit. Separate the lid from the bottom on the tablesaw, sawing the box in two parts along the layout lines.

MDF Support block, same thickness as template, attached with hot glue Straight-fluted router bit Cuttingboard blank 2. Saw out the Center Bandsaw close to each wall of routed groove. Cutting board Routed wall 3. Finish with a Flush Cut Bandsawn surface Bearing rides routed wall. Route. -deep groove creates smooth, accurate reference edges for the next steps. Get to final depth in multiple passes. Routed wall Saw. Before sawing, Lewis darkens the corners of the groove with a pencil for visibility.

Thick stock that’s 3 in. wide. I prefer to use a straight grain that brings the eye to the center of the piece. The front feet are made from sequentially sawn pieces that are mitered and splined. Cut the groove for the spline on the tablesaw using a 45° block Clamp the assembly. Latta uses a wide, double-wrapped rubber band to clamp the assembly. He uses the negative-image offcuts from the scrollsaw as cauls for gluing the feet to the cove molding. mounted to a miter gauge. Cut the spline from 1⁄ 8-in.